Company news

Freshness Keeper introduces new equipment to help new “intelligent” manufacturing

After the arduous fight against the epidemic, Freshness Keeper is still actively planning for development. In order to meet the needs of the market and users, FK has made great efforts in equipment introduction, product development, technology research and development, expand the market space, and strive to make the enterprise bigger, stronger, more refined and more detailed. In November, we just purchased a batch of injection molding machine equipment to further expand the product line and improve the modernization and intelligence of technical equipment.

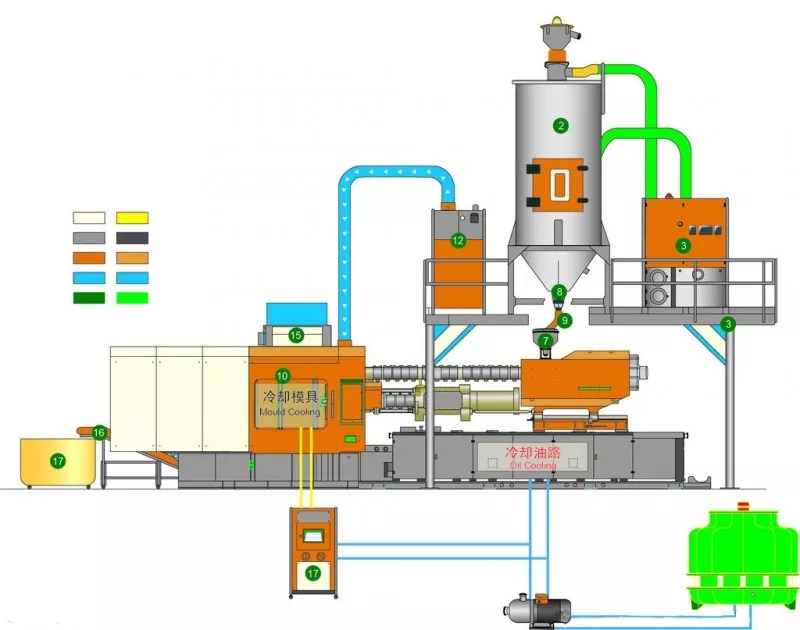

Injection molding machine: It is an important molding equipment for plastic food containers with certain geometric shape and dimensional accuracy, which is used to make plastic by heating and melting, and apply certain pressure, so that the high temperature melt is filled into the mold, and then cooled and cured.

The following are some of our common food container injection molding machines:

Horizontal injection molding machine features:

1, even the mainframe due to the low fuselage, there is no height limit for the plant.

2, the product (food container manufactured products) can automatically fall the occasion, without the use of manipulator can also achieve automatic molding.

3, due to the low fuselage, convenient material supply, easy maintenance.

4. The mold shall be installed by the crane.

5, multiple sets of parallel arrangement, molding products (food containers) are easy to be collected by the conveyor belt packaging.

In order to more standardized, more reasonable, more quickly to complete the injection molding process parameter debugging, increase the service life of the injection molding machine and mold, reduce machine and trim die plane reservation time, reduce manpower, reduce material, improving the quality of food container products and improve production efficiency, eventually to ensure smooth and stable production, Freshness Keeper engineering department formulate debug this injection molding machine safety guidelines:

1.Check whether the machine type matches the size of the mold according to the size of the mold before the mold; According to the length of the mold, set the thickness of the mold in the appropriate position; Lift the mold from the ground or forklift into the machine compartment. The position of the mold inlet is basically in line with the gun nozzle. Open the motor for the nozzle. After a good mouth, tight horse, oil and water.

2.Idling, check the mold, open the side lock, and adjust the mold opening speed to 5%-10%, slowly open the mold, at the same time, keep your eyes on the mold, see if there is any abnormality, immediately stop the machine for inspection.

3.Set molding parameters, before commissioning, need to follow up the characteristics of the added raw materials baking good raw materials; Add to the machine drying hopper, continue drying material.

4.Die down, after the completion of production, first shut off the motor, and then remove the water pipe, oil pipe; After that, the water in the mold is blown out with the air gun to prevent the mold from rusting; Wipe the oil off the surface of the mold with a rag. The mold is lifted out of the machine and placed on the forklift smoothly.

5.In the process of using the mold, especially in the mold test, it is necessary to review the mold injection formability.

6.Analyze the causes of abnormal appearance quality of food container injection molding parts and put forward solutions.

Equipment is the enterprise scale and level of modernization of a basic logo, intelligent manufacture as a new generation of production mode, is the only way for enterprises to build new core competitiveness, every year Freshness Keeper introduce a large number of advanced production equipment, power of intelligent manufacturing, is the escort the leap-forward development of the enterprise, continued to create maximum value for customers, seeking the biggest development for employees, Make due contributions to society.

Post time: Nov-04-2022