Prototypes moves from conceptual ideas, through concepts, to tangible product proposals. Often a model is produced to better explore these final design concepts. Prototype models can be full-scale or to scales that allow bird-eye views as in the case of large projects.

Freshness keeper believes that it is best to develop the final proposal in a number of prototype itterations, to reduce risk and to optimise the design for production. Costing for tooling and unit costs can be better understood by way of these prototypes.

The type of prototyping required depends on the projects, and may include SLA (stereolithography) for fine detail, 3D printing for more robust components, usually done using ABS plastic.

Often 3D printing using PLA (Polyactide) for colour and form studies is used. There is still a place for fully working models in cases where functional assessment is required.

3D Printing Rapid Prototyping

A computer sends instructions to the 3D printer, which deposits or hardens the material in a preprogrammed pattern, creating layers in succession.

Prototype provides several different types of custom 3D printing services. For rapid prototypes and low-volume production, we offer SLA and SLS rapid prototyping services as an additional option to 3D metal printing.

Object, SLA rapid prototyping, SLS rapid prototyping, and FDM - all processes require file formats to be .stl. Prototypes made using these 3D printing services can be used for engineering testing or as master models for polyurethane vacuum casting molds.

Mold design & tool maker

Freshness Keeper's Engineering Department is an experienced team with creative spirit, who are good in mold design and product development. After years of serving domestic and international customers, we have a deep understanding of the different standards applying to domestic and overseas markets. In order to meet customer needs and increase efficiency, we have been constantly striving to update andl improve both software and equipment. We are sure you will like the result of our efforts.

Our investment in the latest CNC technology and machining automation allows our experienced toolmakers to meet compressed lead times while maintaining our reputation for quality.

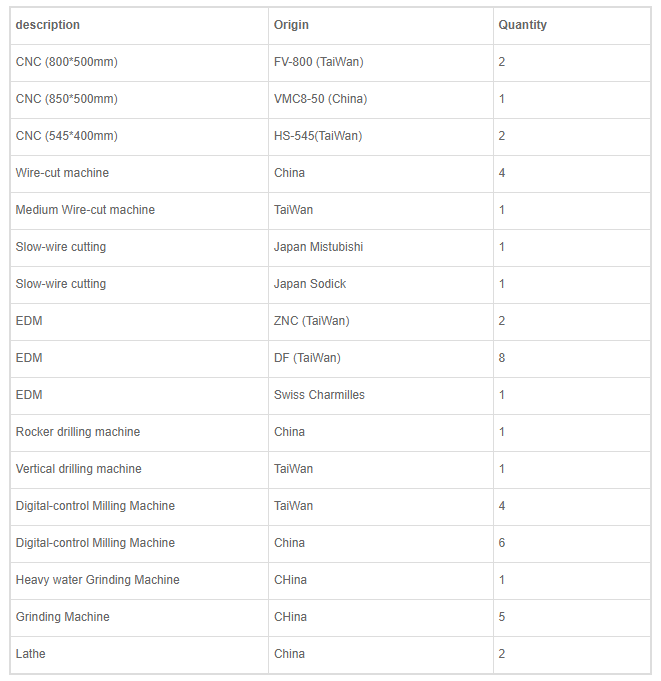

Equipment list

Mould Manufacturing Process:

1. Pro/ENGINEER (3D Modeling)

2. SolidWorks (3D Modeling)

3. AutoCAD (2D Modeling)

4. MoldFlow Mold Advisor (Plastic flow/deform simulation)

5. MasterCAM (CNC Programming)

6. Unigraphics (CNC Programming)

7. CNC Machining Centers

8. CNC EDM's (Electro-Discharge Machining)

9. Wire-Cut Machines.